Film faced plywood sticker process flow

Release Time:

Jun 13,2024

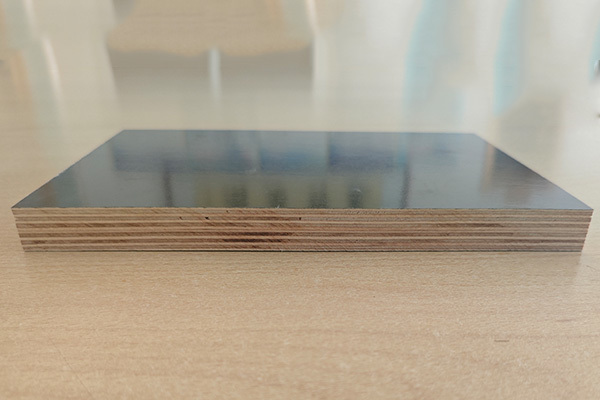

Film faced plywood sticker process flow consists of several key steps to ensure the proper application of the film onto the plywood surface.

Film faced plywood sticker process flow consists of several key steps to ensure the proper application of the film onto the plywood surface.

The first step in the process is surface preparation, where the plywood surface is cleaned and sanded to ensure a smooth and even surface for the film to adhere to. This step is crucial for achieving a high-quality finish and ensuring the longevity of the sticker.

Next, the film faced plywood sticker is carefully measured and cut to size to fit the dimensions of the plywood sheet. Precision is key in this step to ensure a perfect fit and a seamless appearance once the sticker is applied.

Once the sticker is cut to size, it is carefully placed onto the plywood surface and smoothed out to remove any air bubbles or wrinkles. This requires precision and attention to detail to ensure a flawless finish.

After the sticker is applied, it is left to dry and cure before any further handling. This allows the adhesive to fully bond with the plywood surface and ensures a long-lasting and durable finish.

Overall, the film faced plywood sticker process flow requires precision, attention to detail, and careful handling to achieve a high-quality finish that meets the desired specifications. By following these steps, manufacturers can ensure that their film faced plywood products meet the highest standards of quality and durability.

Keywords:

More information